Product Description

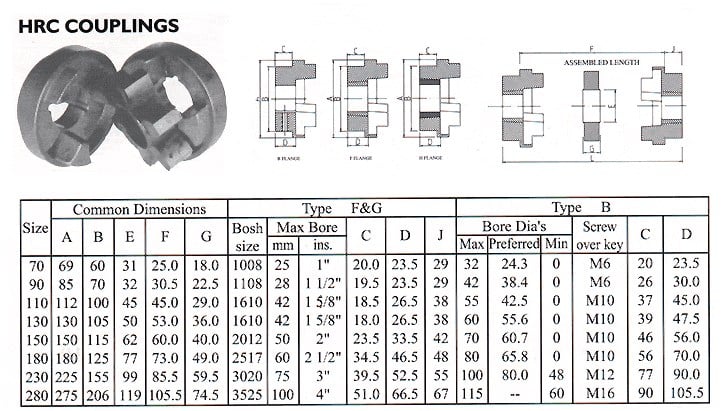

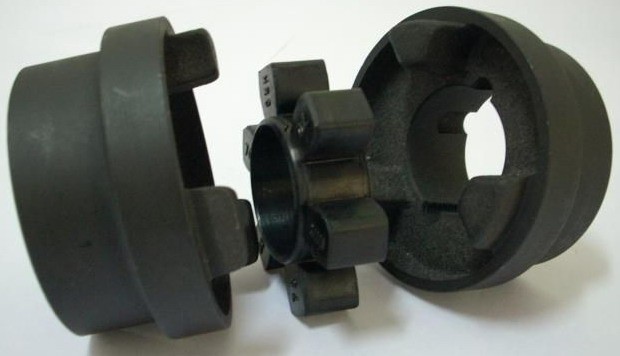

HRC Flexible rubber Camlock shaft coupling types of spider coupling B/F/H Couplings

Product Description

- Installation is quick and easy without special tools required, only a hexagonal wrench is needed

- Maintenance is virtually eliminated without the lubrication required

- The electro-metric element allows HRC to be suitable for use in most conditions

- In the unlikely event of the flexible element being destroyed, the drive will be maintained by the inner action of the integrally cast driving dogs

Product Parameters

| Type F&H | Bored to size | A | B | E | F | G | L1 | L2 | L3 | J | ||||||||

| SIZE | BUSH | Bore | C | D | Bore | C | D | |||||||||||

| MAX MIN | MAX | MIN | ||||||||||||||||

| 70 | 1008 | 25 | 9 | 20.0 | 23.5 | 32 | 10 | 20 | 23.5 | 69 | 60 | 31 | 25 | 18 | 65 | 66.5 | 68 | 29 |

| 90 | 1108 | 28 | 9 | 19.5 | 23.5 | 42 | 10 | 26 | 30.5 | 85 | 70 | 32 | 30.5 | 22.5 | 69.5 | 76 | 82.5 | 29 |

| 110 | 1610 | 42 | 14 | 18.5 | 26.5 | 55 | 10 | 37 | 45.5 | 112 | 100 | 45 | 45 | 29 | 82 | 101 | 119 | 38 |

| 130 | 1610 | 42 | 14 | 18.5 | 26.5 | 60 | 20 | 39 | 47.5 | 130 | 105 | 50 | 53 | 35 | 89 | 118 | 146 | 38 |

| 150 | 2012 | 50 | 14 | 23.5 | 33.5 | 85 | 28 | 46 | 56 | 150 | 115 | 62 | 60 | 40 | 107 | 134 | 160 | 42 |

| 180 | 2517 | 60 | 16 | 34.5 | 46.5 | 80 | 28 | 58 | 70 | 180 | 125 | 77 | 73 | 49 | 142 | 165 | 189 | 48 |

| 230 | 3571 | 75 | 25 | 39.5 | 52.5 | 100 | 48 | 77 | 90 | 225 | 155 | 99 | 85.5 | 59.5 | 165 | 202 | 240 | 55 |

| 280 | 3525 | 100 | 35 | 51.0 | 66.5 | 115 | 60 | 90 | 105.5 | 175 | 206 | 119 | 105.5 | 74.5 | 208 | 247 | 286 | 67 |

Related Products

Company Profile

FAQ

Q: Can you make the coupling with customization?

A: Yes, we can customize per your request.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What’s your lead time?

A: Standard products need 5-30 days, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, and we can provide technical support if you

need.

Q: How do you ship to us?

A: It is available by air, sea, or by train.

Q: How do I pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | Custom |

| Torque: | <10N.M |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample Yellow

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can HRC Couplings Accommodate High Torque and High-Speed Applications?

HRC (Highly Resilient Coupling) couplings are designed to handle a wide range of torque and speed requirements, making them suitable for various industrial applications, including those involving high torque and high-speed conditions. Their ability to accommodate high torque and high-speed applications depends on several factors:

- Coupling Size and Type: HRC couplings come in various sizes and types, each with its torque and speed ratings. Larger couplings with robust designs can handle higher torque and speed than smaller ones.

- Material Composition: HRC couplings consist of a metal hub and a flexible elastomeric element. The material composition of the elastomer plays a significant role in determining the coupling’s torque and speed capabilities.

- Elastomer Properties: The elastomeric element in HRC couplings provides flexibility and damping. It should be selected based on its resilience, durability, and ability to withstand the intended torque and speed requirements.

- Application Requirements: The coupling’s torque and speed ratings must match or exceed the demands of the application. Factors such as the driven and driving equipment’s power, load characteristics, and operational conditions should be considered.

- Proper Installation: Correct installation, including accurate alignment and proper torqueing of the coupling, ensures optimal performance and minimizes the risk of premature failure in high torque and speed applications.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate HRC coupling for a specific high torque and high-speed application. Using an undersized or unsuitable coupling can lead to premature wear, reduced efficiency, and potential safety hazards.

In summary, HRC couplings are well-suited for high torque and high-speed applications when properly selected, installed, and maintained. They offer the benefits of damping vibrations, shock absorption, and misalignment compensation while reliably transmitting power in demanding industrial settings.

Can HRC Couplings Be Used in Applications with Varying Operating Temperatures?

Yes, HRC couplings can be used in applications with varying operating temperatures. The choice of materials used in the manufacturing of HRC couplings allows them to withstand a wide range of temperatures, making them suitable for diverse industrial environments. Here’s how HRC couplings handle varying operating temperatures:

1. Material Selection: HRC couplings are typically constructed using high-quality materials such as cast iron, steel, and a flexible rubber element. These materials are selected for their excellent thermal properties and ability to maintain their structural integrity across a broad temperature range.

2. Temperature Resistance: The rubber element in the HRC coupling is designed to resist temperature extremes. It remains flexible and resilient even in high or low-temperature conditions. This flexibility is essential for the coupling’s ability to accommodate misalignment and dampen vibrations effectively.

3. Thermal Expansion: When machinery operates at higher temperatures, components can undergo thermal expansion. HRC couplings can handle the slight misalignment caused by thermal expansion, thanks to their flexible rubber element. This feature prevents additional stress on the connected shafts and bearings, reducing the risk of premature failures.

4. Lubrication-Free: Unlike some other types of couplings that require lubrication for smooth operation, HRC couplings are designed to be lubrication-free. This is advantageous in applications with varying temperatures because lubricants may experience changes in viscosity and performance at extreme temperatures. The absence of lubrication simplifies maintenance and ensures consistent coupling performance regardless of temperature fluctuations.

5. Application Versatility: Due to their temperature resistance and ability to handle misalignment, HRC couplings find applications in a wide range of industries and equipment, including pumps, compressors, conveyors, and various types of machinery that operate in environments with varying temperatures.

In summary, HRC couplings are well-suited for applications with varying operating temperatures. Their robust construction, temperature-resistant materials, and ability to handle misalignment make them a reliable and versatile choice for power transmission in different industrial settings, regardless of temperature fluctuations.

Selection of HRC Coupling for Specific Applications

Choosing the appropriate HRC coupling for a specific application requires careful consideration of several factors. Here are the steps to select the right HRC coupling:

- Identify Application Requirements: Understand the specific requirements of your application, including torque and speed requirements, operating environment, shaft misalignment, and space limitations.

- Calculate Torque and Speed: Determine the torque and speed values required for your application. This information will help you select an HRC coupling that can handle the expected load and rotational speed.

- Consider Misalignment: Evaluate the type and magnitude of misalignment that the coupling needs to accommodate. HRC couplings can handle angular, parallel, and axial misalignment to varying degrees, so choose a design that meets your misalignment needs.

- Check Space Constraints: Consider the available space for the coupling. If space is limited, you may need a compact HRC design or consider other coupling types that require less space.

- Choose Hub Material: Select the hub material based on the application environment. Standard HRC hubs are usually made of cast iron, but stainless steel or other materials may be necessary for corrosive or specialized applications.

- Explore Design Variations: Evaluate the various HRC coupling designs available, such as standard, spacer, flywheel, taper lock, brake drum, etc. Choose a design that best suits your application’s needs.

- Consider Environmental Factors: If your application operates in harsh conditions, consider factors such as temperature, moisture, chemicals, and potential contamination when choosing the HRC coupling.

- Check Installation and Maintenance: Consider the ease of installation and maintenance requirements of the selected HRC coupling. Some designs, such as taper lock or pilot bore, offer easier installation and removal.

- Consult Manufacturer Recommendations: Consult with the coupling manufacturer or a knowledgeable supplier to ensure you select the right HRC coupling for your specific application. They can provide valuable insights and recommendations based on their expertise.

By carefully evaluating these factors and selecting the appropriate HRC coupling, you can ensure optimal performance, reliability, and longevity for your mechanical system.

editor by CX 2024-04-03

by

Tags:

Leave a Reply