Product Description

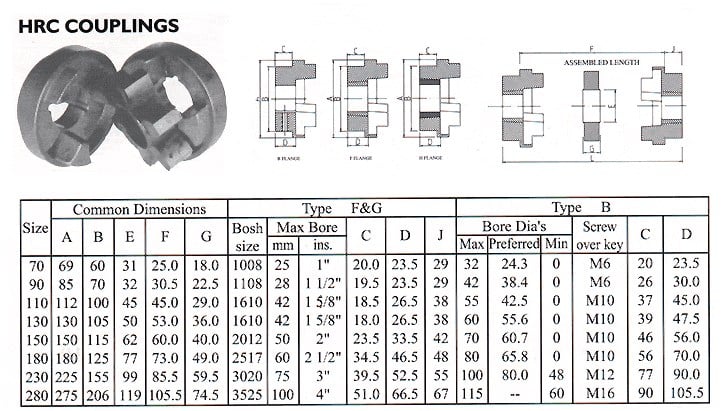

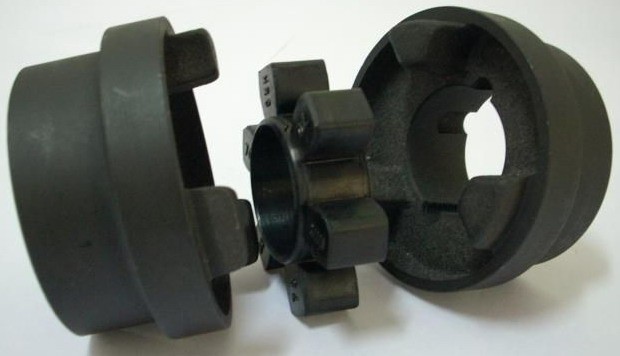

Cast Iron HRC flexible couplings

1. Installation: Is quick and easy without special tolls, only a hexagon wrench is required.

2. Maintenance: Is virtually eliminated and no lubricant is required

3. Environment: The elastomeric element mades HRC suitable for use in most conditions.

4. Material: Cast iron

5. Size: HRC70, HRC90, HRC110, HRC130, HRC150, HRC180, HRC230, HRC280.

6. Type: B flange, F flange, H flange. We are professinal manufacturer for various couplings. With good quality and best price.

We can also supply other types coupling as below:

NM: 50-214

MH: 55-230

L: 35-150

CL: 90-225

HRC: 70-280

FCL: 90-280

GE coupling: 19-90

Bowex coupling: 14-65

We can also supply chain coupling, roller chain coupling, rigid couplings, flexible couplings, fcl coupling, flexible rubber fcl coupling, fcl flexible coupling, forged steel fcl coupling, flexible coupling fcl, fcl flexible shaft coupling, jaw coupling, hrc coupling, CHINAMFG coupling, cast steel coupling, aluminum coupling, stainless steel coupling, pin coupling, mh coupling, nm coupling, spacer coupling, taper lock rigid coupling, flange coupling, sleeve coupling, nylon sleeve gear coupling, gear coupling, crc coupling, js coupling

Competitive Advantage:

More than 20 years advanced technology and experience of us will give strong support for the coupling you need. We will understand your need of product quickly, and give quick respond and good service. A lot of cases of our products will show you that it worth your trust.

Under the full quality control system, our products go through the precise product line and strict testing process. We have excellent working flow and standard to ensure stability, products reliable enough for using.

Take our scale economy, raw material superiority, and CHINAMFG for clients to account, our price do have a great competitiveness. They are good value and cost effective than your imagine.

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Connection: | Female |

|---|---|

| Structure: | Roller Chain |

| Flexible or Rigid: | Rigid |

| Material: | Iron |

| Standard: | Standard |

| Module: | HRC90 |

| Customization: |

Available

| Customized Request |

|---|

How Does an HRC Coupling Protect Connected Equipment from Shock Loads and Vibrations?

HRC (Highly Resilient Coupling) couplings are designed to protect connected equipment from shock loads and vibrations through their unique construction and material properties:

- Flexible Elastomeric Element: The key component of an HRC coupling is the flexible elastomeric element positioned between the two metal hubs. This elastomer acts as a mechanical buffer, capable of absorbing and dissipating shock loads and vibrations that may occur during operation.

- Damping of Vibrations: The elastomeric element’s flexibility allows it to dampen torsional vibrations and dampen the impact of sudden shock loads. This helps in reducing resonance effects and minimizing the transmission of vibrations to the connected equipment.

- High Resilience: HRC couplings are made from elastomers with high resilience, meaning they can deform under load and return to their original shape after the load is removed. This property enables them to absorb and dissipate energy, protecting the system from sudden shocks.

- Misalignment Compensation: In addition to shock and vibration absorption, HRC couplings can also compensate for small amounts of misalignment between shafts. This capability further enhances the protection of connected equipment by reducing the stress caused by misalignment.

When equipment experiences shock loads or vibrations, the elastomeric element flexes and compresses, acting as a shock absorber. This prevents the sudden transmission of high impact forces to the connected machinery, reducing the risk of damage and premature wear.

Moreover, by damping vibrations, HRC couplings improve the overall stability and smoothness of the power transmission system. This contributes to the longevity of connected equipment and reduces the likelihood of mechanical failures or downtime.

Overall, HRC couplings play a vital role in safeguarding connected equipment from shock loads and vibrations, promoting the reliability and performance of mechanical systems in various industrial applications.

What Role Does an HRC Coupling Play in Reducing Downtime and Maintenance Costs?

An HRC (Highly Resilient Coupling) plays a significant role in reducing downtime and maintenance costs in mechanical systems. Here’s how:

1. Vibration Damping: HRC couplings are designed with a flexible rubber element that acts as a vibration damper. The rubber element absorbs and dampens vibrations generated during the operation of rotating machinery. By reducing vibrations, the coupling helps prevent excessive wear and fatigue on connected equipment, such as motors, pumps, and gearboxes. This leads to less frequent breakdowns and extends the lifespan of components, ultimately reducing downtime for repairs and replacements.

2. Misalignment Compensation: As mentioned earlier, HRC couplings can handle various types of misalignment, including angular, parallel, and axial misalignment. By accommodating these misalignments, the coupling helps prevent additional stress on the connected shafts and bearings. The ability to handle misalignment reduces the likelihood of premature failures and breakdowns caused by misalignment-related issues.

3. Shock Load Absorption: In many industrial applications, rotating machinery may experience sudden shock loads due to various factors like sudden starts, stops, or changes in load. The flexible rubber element in the HRC coupling acts as a shock absorber, cushioning the impact of these sudden loads. By absorbing shock loads, the coupling protects the connected equipment from damage and minimizes the risk of unexpected downtime due to shock-related failures.

4. Easy Installation and Maintenance: HRC couplings are relatively easy to install and maintain. They do not require complex alignment procedures, and the flexible element eliminates the need for lubrication. The simple design and ease of maintenance contribute to reducing the time required for installation and upkeep, thus lowering overall maintenance costs.

5. Cost-Effective Design: HRC couplings are cost-effective compared to some other types of couplings. They provide reliable performance and durability at a reasonable price point. The cost-effectiveness of HRC couplings makes them a popular choice in various industrial applications where reducing operational costs is a priority.

Overall, the HRC coupling’s ability to dampen vibrations, compensate for misalignment, absorb shock loads, and offer easy installation and maintenance translates into improved reliability and efficiency of mechanical systems. This, in turn, leads to reduced downtime and maintenance costs, making HRC couplings a valuable component in power transmission applications across industries.

Explanation of HRC Coupling and Its Functionality

An HRC coupling, also known as a “Highly Resilient Coupling” or “Jaw Coupling,” is a type of flexible shaft coupling used to connect two shafts in mechanical power transmission systems. It is designed to transmit torque while accommodating minor shaft misalignments and dampening vibrations.

How HRC Coupling Works:

The HRC coupling consists of three main components:

-

Two Hubs: Each hub has a set of curved jaws with teeth that mesh together when the coupling is assembled. The hubs are typically made of steel or cast iron and are connected to the respective shafts of the driving and driven equipment.

-

Elastomeric Spider: The elastomeric spider is the flexible element of the coupling and is placed between the two hubs. It is commonly made of a synthetic rubber material such as polyurethane. The spider’s unique design allows it to deform under torque, transmitting power while accommodating angular and parallel misalignments between the shafts.

When the HRC coupling is in operation, the driving shaft rotates, and the torque is transmitted through the hubs to the elastomeric spider. As the spider deforms, the jaws of the hubs move relative to each other, accommodating any misalignment between the shafts. This flexibility helps to reduce the transmission of vibrations and shock loads from one shaft to the other, thus protecting the connected equipment.

HRC couplings are widely used in various applications, including pumps, compressors, conveyors, and other machinery, where misalignment and shock absorption are important considerations. Their simple and effective design makes them easy to install and maintain, and they are available in various sizes and torque ratings to suit different power transmission requirements.

editor by CX 2024-04-09

by

Leave a Reply